Lan Luo, Fenghua Zhang, Jinsong Leng

Composites Science and Technology, 2021, 108899.

DOI: https://doi.org/10.1016/j.compscitech.2021.108899

Shape memory epoxy resins are one of the most widely used engineering intelligent polymers, mainly used in aerospace, intelligent bionics, and other fields of active deformation structures. A series of shape memory epoxy resins with a narrow transition temperature range, showing strong inter-segment forces and regular uniform cross-linked networks are designed and synthesized. By adjusting the stoichiometry and cross-linking density, the length of the segments is uniformly controlled. The glass transition temperature range can reach 14-23°C, which improves the efficiency of shape memory action. Moreover, the addition of epoxy-terminated liquid nitrile rubber (ETBN) composites can toughen the system. Furthermore, combing the two-stage curing method, and selecting the nano-particle high-temperature latent curing agent , the super curing effect is achieved, Tg, modulus and strength of composites are improved. The resulting composites are appropriate for shape fixation and recovery temperature with more precision and closer distance between, which can meet the higher requirements of the aerospace field.

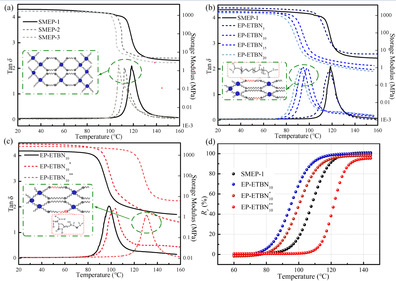

Figure 1. (a) and (b) The DMA curves of systems.

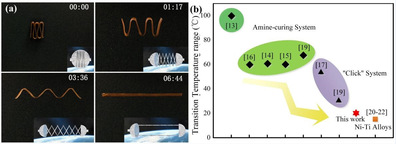

It is worth mentioning that all the samples were shaped by applying external forces when they were heated to Tg, and the external forces were removed when they did not need to be cooled to room temperature. After leaving the heating table for a few seconds, the shape can be fixed, thus improving the action efficiency of shape memory. The multi-amine epoxy resin samples were simultaneously recovered at Tg+20°C. The decrease in the degree of crosslink of the system results in a relatively small resistance to the movement of the segments. The deformation recovery ability is improved as the amount of active hydrogen increases. When the recovery rate was increased, the recovery time was shorter.

Figure 2. (a) Simulation process of space capsule; (b) The transition temperature range performance is compared with other literature.