Chengjun Zeng, Liwu Liu, Wenfeng Bian, Jinsong Leng, Yanju Liu

Additive Manufacturing 38 (2021) 101842.

DOI:10.1016/j.addma.2021.101842

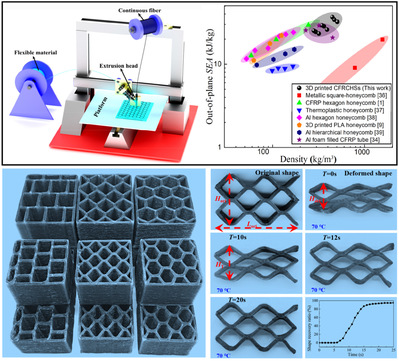

Three-dimensional (3D) printing is a potential rapid prototyping process that can replace conventional manufacturing processes to fabricate lightweight cellular structures with superior energy absorption properties. In this work, continuous fiber-reinforced composite honeycomb structures (CFRCHSs) with excellent shape memory properties were fabricated by fused filament fabrication (FFF) technology, and their out-of-plane/in-plane compression behavior and energy absorption characteristics were experimentally investigated. It was found that the failure process of 3D-printed CFRCHSs under in-plane loading is that the honeycomb cells collapse layer by layer along the loading direction while forming localized bands. The crashworthiness analysis indicates that the 3D printed CFRCHSs outperform several competitive cellular topologies in terms of compression strength and specific energy absorption. In addition, shape recovery tests demonstrate that 3D printed CFRCHSs possess the potential to serve as a key element of lightweight smart systems and tunable energy absorption devices.