1. Deployable Space Structures

The fiber-reinforced shape memory polymer composite (SMPC) is naturally considered to be manufactured with the characteristics of low density, low cost, high reversible strain, high strength, high modulus, high stiffness, good resistance against creep, and relatively high recovery stress. So, the SMPC has good control of deployment of the space structure, reduces the complexity of the space structure, and improves the stability of the deployment.

(a) The local post-buckling theory is required for the unidirectional fiber reinforced composite materials at the conditions of its large geometrical deflection. On this basis, the analysis of buckling deformation for SMPC was proposed.

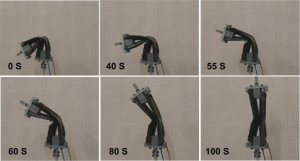

(b) A solar panel was deployed actuated by actuated SMPC hinge under the simulated ground-based weightlessness conditions. Compared to the traditional metal twist spring type hinge drives and motor type mechanical control launch devices, SMPC hinge driving device has numerous advantages including: simple structure, light, easy supervision and control, facilitates repeat process, and design flexibility.

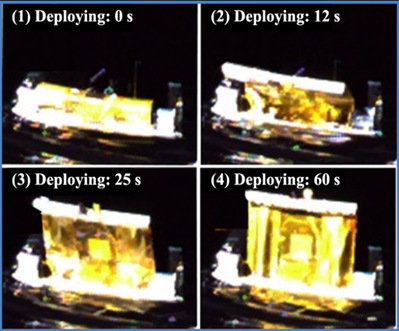

(c) The flexible solar array system based on lenticular collapsible SMPC tube have been developed, and successfully completed the on orbit verification. To the best of our knowledge, this is the first on-orbit controllable deployment of a flexible solar array system based on SMPC in the world.

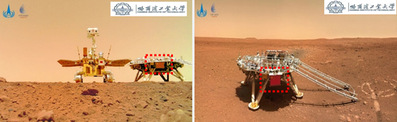

(d) The locking-releasing device of the Chinese national flag have been designed and fabricated, and successfully launched with Tianwen-1 Mars probe in 2020. This device achieved controllable deployment on Mars in 2021. To the best of our knowledge, this is the first application of SMPC deployable structure in deep space exploration in the world.

Fig. 1 The snap-shot images during the deployment of hinge

Fig. 2 On orbit verification of flexible solar array system based on SMPC structure

Fig. 3 The deployment schematic of the locking-releasing device of the Chinese national flag

Fig. 4 Photo of the Rover and Lander of Tianwen-1 Mars probe

2. Morphing Structures

Morphing technologies could enable aircraft to be more efficient and operate under a wide range of varying flight conditions. It provides the ability to maximize the aircraft performance, expand its flight envelope, replace conventional control surfaces, and reduce drag to improve range. The morphing concept changes shape dramatically via a morphing wing such as a folding a sliding, or a variable camber wing.

Now, our group focuses on the following issues in morphing structures:

(a) Morphing skins, which are not only enable transformable but also support aerodynamic loads,

(b) Smart actuators, which show good performances in lightweight and high-output,

(c) Adaptive structures, which could change the parameters of wing area, backswept, aspect ratio, twisting, wing camber, etc. under different flight conditions.

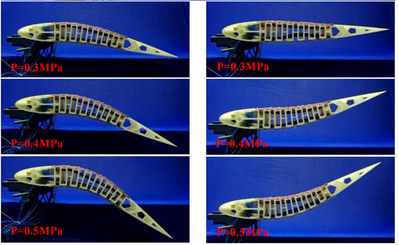

Fig. 5 The variable camber wing based on Shape Memory Polymer skin

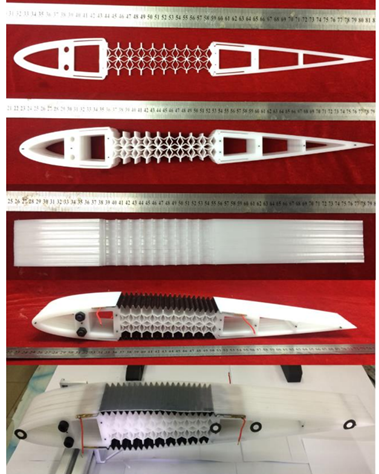

Fig. 6 The morphing wing structure based on pneumatic muscle fibers

Fig. 7 Fabrication process of a variable camber wing sample