4D printing technology adds the dimension of transformation over time, allowing 3D printed structures to actively and dynamically change in shape or properties. 4D printing can be achieved by using intelligent materials (e.g., shape memory polymers, SMPs) as raw materials for 3D printing.

The use of 4D printing for the preparation of biomedical devices enables the device to have a patient-tailored configuration, which can effectively avoid complications such as wear, displacement, and embolization due to device size mismatch. In addition, the programmability of 4D-printed biomedical devices allows for active control of their configuration and performance. Particularly, the combination of multifunctional printable SMP biomaterials and remotely controlled actuation methods enables 4D printed biomedical devices not only with patient-tailored configurations but also with enhanced functionality, as well as automatic deployment in a controlled manner at hard-to-reach locations in vivo.

We have developed a variety of 4D-printed shape memory polymer biomedical devices, including occlusion devices, orbital bone stents, tracheal stents, vascular scaffolds, and intestinal scaffolds, which enable customized configurations and performance, as well as remotely controllable deployment.

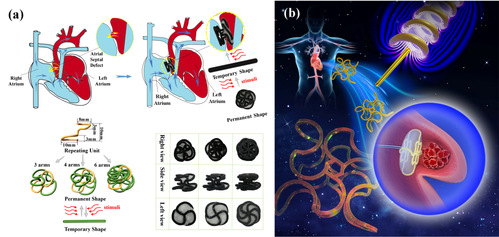

Fig. 1 4D printed shape memory occlusion devices. (a) atrial septal defect (ASD) occlusion devices; (b) left atrial appendage (LAA) occlusion devices

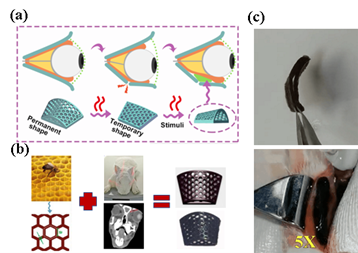

Fig. 2 4D printed shape memory orbital bone stents. (a) Schematic of 4D printed orbital stent for enophthalmos treatment; (b) Stent design; (c) Shape recovery process